A Cost Analysis of Mobile and Stationary Pellet Mills for Mitigating Wildfire Costs

Journal of Sustainable Bioenergy Systems,

Ryan Jacobson, Shahab Sokhansanj, Dominik Roeser, Jason Hansen, Bhushan Gopaluni, Xiaotao Bi

[PDF]

Abstract

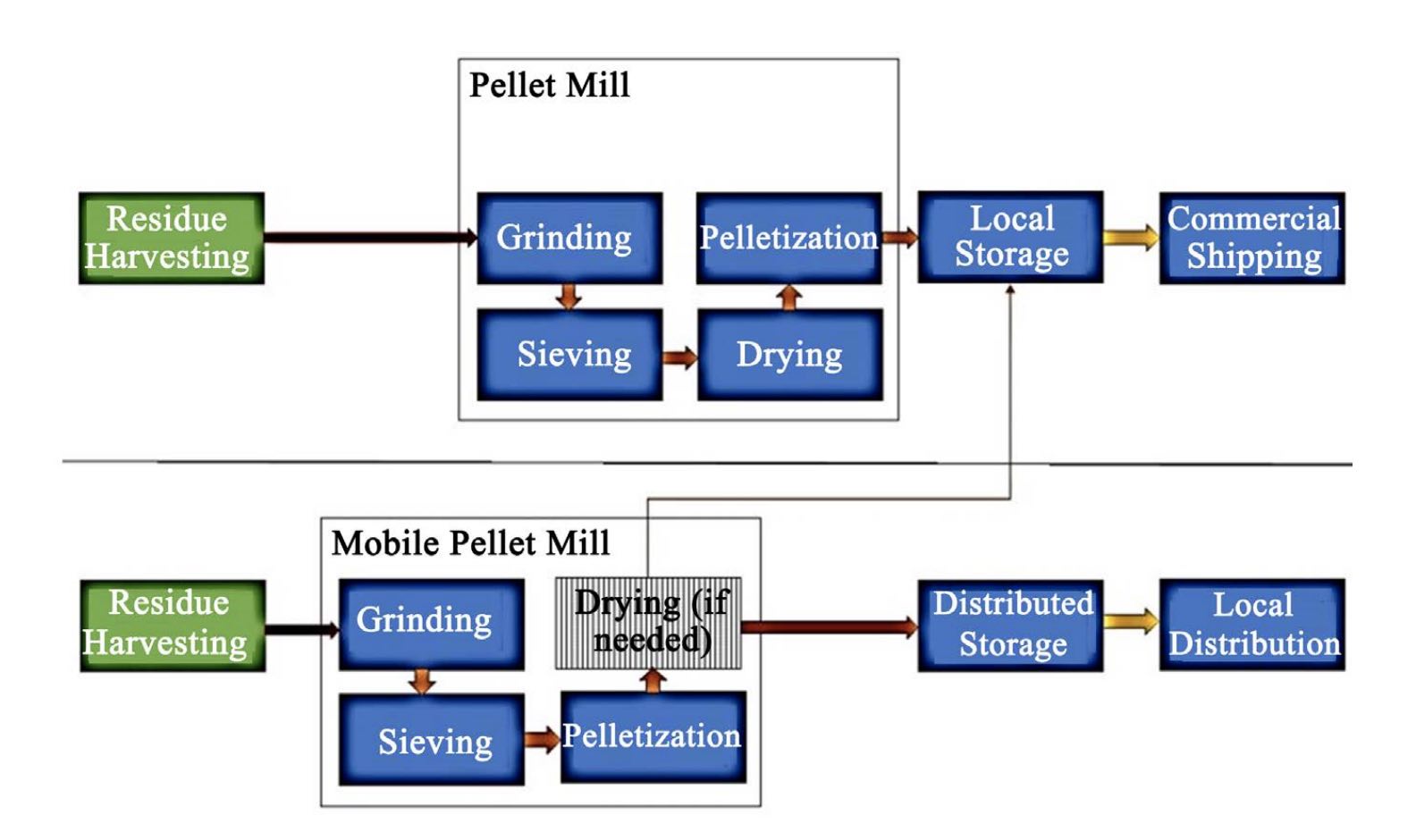

A comparison of traditional and mobile wood pellet mills found that mobile systems had higher production costs. Wildfire suppression costs have consistently exceeded British Columbia’s budget set for such activities. Pelletization of excess wood for bioenergy applications has been proposed as a possible method of reducing the overall costs of fighting wildfires. In this study, a traditional pellet mill produces wood pellets from new, marginal feedstocks for $182.24 ± 24.47 tonne−1 and a mobile pellet production system produces wood pellets for $402.71 ± 24.18 tonne−1 . The traditional pellet mill produces 90,000 tonnes∙yr−1 with harvest residues being collected in the forest, transported to the pellet mill, dried, chipped, pelletized and then stored. The mobile system collects harvest residues from the forest, transports them to the forest landing where the trailer-mounted mobile pellet system is established and is then ground, pelletized and dried if needed. The mobile system uses a novel high moisture pelletization system and harvest residues to heat the biomass dryer used in the system. The mobile pellet system requires 22 systems to produce 90,000 tonnes∙yr−1 and each system should relocate 9 times in a year to minimize production costs related to feedstock quality and scarcity. These mobile pellet systems can allow increased forest management in forest areas at high risk for wildfires and reduce the cost of suppressing wildfires in treated areas.

Read or Download: PDF