Determining the amount of 'green' coke generated when co-processing lipids commercially by fluid catalytic cracking (FCC)

Biofuels, Bioproducts and Biorefining,

Jianping Su, Liang Cao, Gary Lee, Bhushan Gopaluni, Don O’Connor, Susan van Dyk, Robert Pinchuk, Jack Saddler

[PDF]

Click to enlarge image.

Abstract

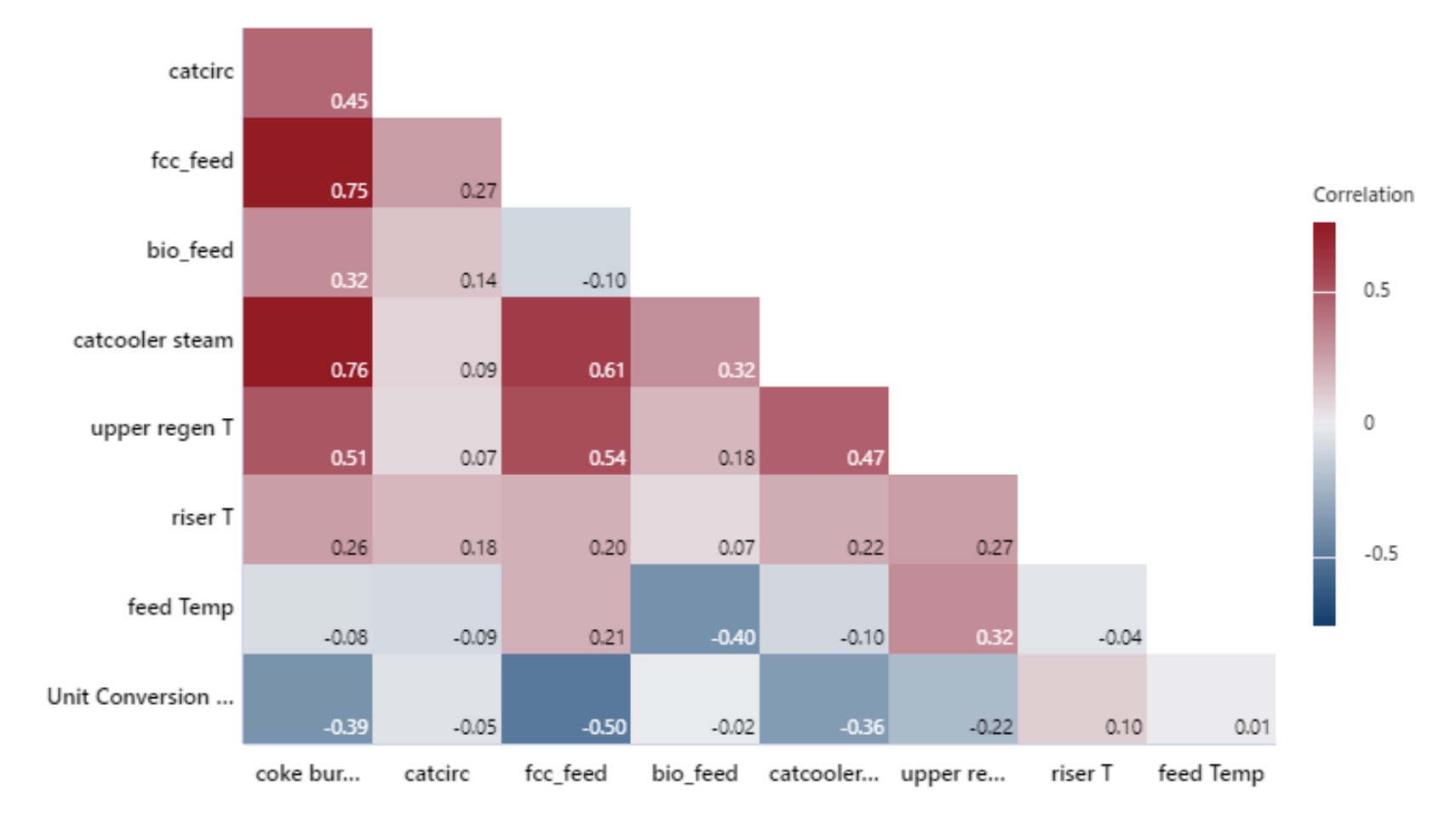

Co-processing biogenic feedstocks in oil refineries will reduce the greenhouse gas emissions normally associated with fossil-derived transportation fuels. The fluid catalytic cracker (FCC) within a refinery is a robust processing unit and will probably be a preferred insertion point if biocrudes, produced by the liquefaction of biomass, are co-processed within a refinery. Fluid catalytic cracking results in a wide range of intermediate products which can be upgraded to gasoline, diesel, heavy fuel oil and liquified petroleum gas blendstocks. Coke is also produced and provides heating for feedstocks, the endothermic catalytic cracking reactions and the regeneration of the FCC catalyst. However, coke combustion also generates carbon dioxide and is a significant source of refinery greenhouse gas emissions. As detailed here, the continuous nature of the process makes the physical evaluation of any biogenic coke fraction, via methods such as C14 isotope analysis, quite challenging. However, quantifying the stack gases provides one way of assessing the renewable content of the carbon dioxide derived from coke combustion. The hourly data from 1year of commercial operation was assessed using linear and Bayesian ridge regression to quantify the burning coefficient of the coke when co-processing lipids at the FCC.

Read or Download: PDF